Why sintered stone is cheaper than quartz stone? To start with, the raw materials like silica, feldspar and clay minerals are generally and comparatively cheaper than quartz sand and resin to manufacture quartz slabs. In one word, the sintered stone saves original cost from some raw materials. Additionally, modern production line of the sintered stone is mature and highly automated, which requires less maintenance personnels and realize high output of qualified products. That means we don't need to invest much labor cost like manufacturing quartz slabs and in other side save personnel cost. Also more output of qualified sintered stone will finally avoid waste and cut price down for end clients. What's more, the popular thickness of the sintered stone is 3mm, 6mm and 12mm, thinner than popular 15mm, 18mm, 20mm and even 30mm of quartz slabs. It also saves shipping cost for buyers, because it can load more in the same container. Therefore, from many aspects, the sintered stone is more advantageous in production cost and final prices, which is better for many average families. To be honest, they can enjoy the modern high quality stone materials, with acceptable prices.

Size: 3200*1600*12mm;2400*1200*6mm; 2700*1200*6mm; 3000*1200*3mm;

Surface: Matt; Polished; Digital glazing; Velvet;

Package: A-frame steel package or sea-worthy wood bundles;

Application: Kitchen appliances and home panel; Interior wall and floor; Bathroom space; Custom furnishing; Door panels; Stairs; Furnitures; Exterior wall;

Features:

1. Great amount of in-stock slabs with various colors and sizes for fast shipment;

2. Advanced manufacturing equipment and half-automated production line;

3. Mature management teams and clean working space;

4. Easy to match quartz slabs in full container;

5. Custom slab size and thickness;

6. Small MOQ for each color;

7. Competitive prices;

8. Free samples;

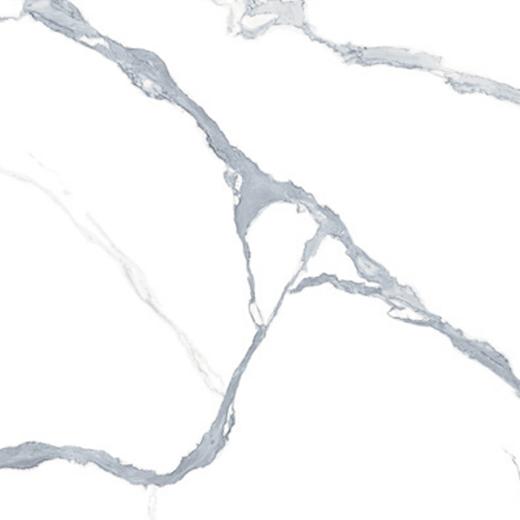

Photos:

Other designs: