The sintered stone is leading artificial stone material for modern design of interior spaces. It is manufactured with a mixture of mainly clay, feldspar, silica and natural mineral oxides, under a even press of thousands of tons and a heating temperatures over 1200°C - 1400°C .The whole process is similar to the formation procedures of natural stone like granite or marble, formed deep within the earth, but the sintered stone is just accelerated and controlled in a professional manufacturing workshop. It is made to mimic the beauty of various natural stone materials, like granite, marble, quartzite, and travertine, etc. More importantly, the sintered stone slabs are produced to avoid different negative features of natural stones, such as crack, color inconsistency, instability of material supply, etc. In one word, the sintered stone make full use of good features of natural stone and optimize other negative features to become a perfect artificial stone for architects, designers, project contractors and house owners, etc.

Size: 3200*1600*12mm;2400*1200*6mm; 2700*1200*6mm; 3000*1200*3mm;

Surface: Matt; Polished; Digital glazing; Velvet;

Package: A-frame steel package or sea-worthy wood bundles;

Application: Kitchen appliances and home panel; Interior wall and floor; Bathroom space; Custom furnishing; Door panels; Stairs; Furnitures; Exterior wall;

Features:

1. Great amount of in-stock slabs with various colors and sizes for fast shipment;

2. Advanced manufacturing equipment and half-automated production line;

3. Mature management teams and clean working space;

4. Easy to match quartz slabs in full container;

5. Custom slab size and thickness;

6. Small MOQ for each color;

7. Competitive prices;

8. Free samples;

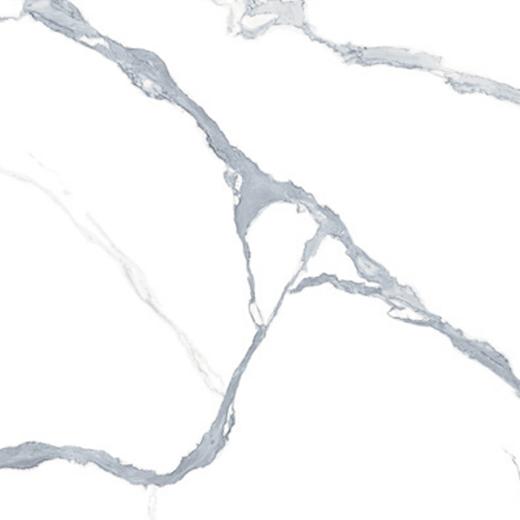

Photos: