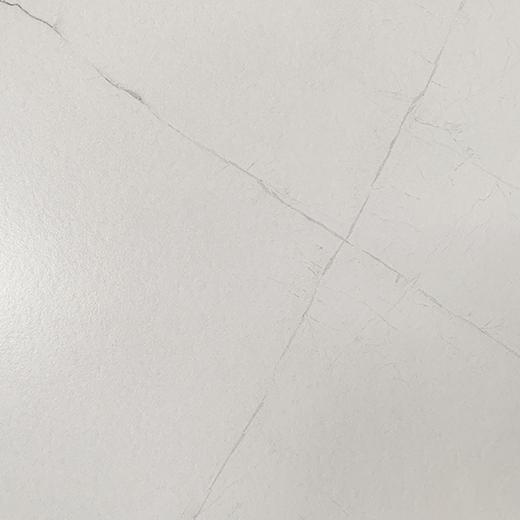

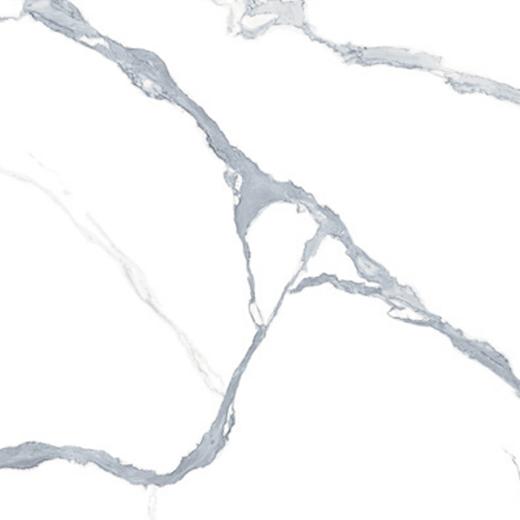

What are the most popular stone materials for many Latin American families? The answer is quartz and sintered stone. Both artificial stone choices have occupied over 80% of stone materials in local market. The quartz slabs have been accepted universally in Latin American countries since 2013. While in recent years, the sintered stone slabs or so-called porcelain has been getting similarly popular in local stone market. Why more people prefer this sintered stone for their kitchen countertop and wall or floor building? Now, the most popular size of sintered stone is 3200*1600*12mm, thinner than popular quartz slab thickness choices like 18mm or 20mm. It means that our buyers can load more quantities for each container, which saves their shipping cost and makes this stone material more competitive in prices. Actually, with various designs and colors, the sintered stone is comparatively cheaper than most of other stone materials, which helps many average families realize modern home decoration in limited budget. Besides of price advantage, there are also many other reasons to explain the popularity of sintered stone. For example, the chemical and physical features of sintered stone can well compete with other stone materials, like its perfect resistance to heat, water, scratch. Moreover, our clients have flexible choices of color patterns as well as slab sizes and thickness. And we have a lot of different slabs in stock for fast shipment. Of course, like other engineered stone materials, we also are able to do customized colors for you. Anyway, the perfect artificial stone material, sintered stone, will receive much more popularity in coming days.

Size: 3200*1600*12mm;2400*1200*6mm; 2700*1200*6mm; 3000*1200*3mm;

Surface: Matt; Polished; Digital glazing; Velvet;

Package: A-frame steel package or sea-worthy wood bundles;

Application: Kitchen appliances and home panel; Interior wall and floor; Bathroom space; Custom furnishing; Door panels; Stairs; Furnitures; Exterior wall;

Features:

1. Great amount of in-stock slabs with various colors and sizes for fast shipment;

2. Advanced manufacturing equipment and half-automated production line;

3. Mature management teams and clean working space;

4. Easy to match quartz slabs in full container;

5. Custom slab size and thickness;

6. Small MOQ for each color;

7. Competitive prices;

8. Free samples;

Photos: