The non-silica policy brought stop to normal engineered quartz slabs. Australian stone wholesalers or fabricators have no other choices but change to non-silica glass stone slab, with nearly same looking to former quartz slabs or sintered stone, so-called porcelain slabs. Actually, before the policy was effected, the sintered stone has been universally fabricated for kitchen countertop or wall cladding. After the policy, the needs of sintered stone is already doubled or even more. Many stone fabricators find it more beneficial to use sintered stone slabs for home decoration. Firstly, sintered stone could be used in outdoor areas, like outside table tops, wall and floor, without deforming or color fading. Secondly, formerly Australia clients bought quartz slabs with 20mm or 30mm thickness, which were so heavy that they need tools to transfer the slabs. Now sintered stone has thickness of 12mm, 9mm and even 6mm thickness, which is much lighter than other stone materials. The most popular size is 3200*1600*12mm which is strong enough to avoid easy breaking during shipment and more importantly, much lighter for two workers to move by labor. And secondly, because of non-stop of sintered stone production line, we keep manufacturing various sintered stone patterns in all year round. Therefore, we have many sintered stone slabs in stock for prompt shipment or small MOQ to match various colors. With various sizes and thickness, it rends our clients much more flexibility to purchase sintered stone slabs and match customized needs.

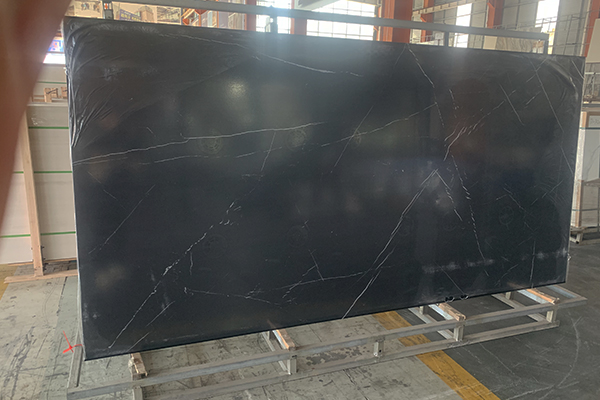

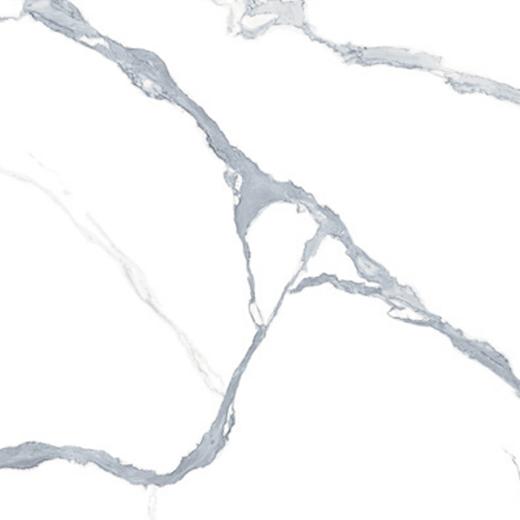

Size: 3200*1600*12mm;2400*1200*6mm; 2700*1200*6mm; 3000*1200*3mm;

Surface: Matt; Polished; Digital glazing; Velvet;

Package: A-frame steel package or sea-worthy wood bundles;

Application: Kitchen appliances and home panel; Interior wall and floor; Bathroom space; Custom furnishing; Door panels; Stairs; Furnitures; Exterior wall;

Features:

1. Great amount of in-stock slabs with various colors and sizes for fast shipment;

2. Advanced manufacturing equipment and half-automated production line;

3. Mature management teams and clean working space;

4. Easy to match quartz slabs in full container;

5. Custom slab size and thickness;

6. Small MOQ for each color;

7. Competitive prices;

8. Free samples;

Photos: