How can you fabricate sintered stone countertops in an effective way? To start with, you need to purchase sintered stone slabs from reliable supplier. Actually, there are not many manufacturers of sintered stone slabs in china. Most of sintered stone suppliers are trading companies or agents to these limited manufacturers who produce different quality of sintered stone with various prices. No matter from direct manufacturer or middle agent, quality should be first to consider. Of course, the prices should be reasonable. Similar to ceramic tiles, the sintered stone slab is think and easy to chips during cutting process. Good quality sintered stone is made under higher heat and pressure with better production line, so it has better density and hardness to avoid chips. Secondly, you need sharper cutting diamond saws which can run fast and stably, also to avoid chips during the cutting. There are specialized cutting discs for sintered stone slabs. We sometimes also recommend some reliable supplier of cutting discs for our sintered stone clients. Lastly, the experienced labor workers to fabricate sintered stone countertops are important. They care more for details during cutting, sticking, and installing, which can better ensure perfect finished countertops to install safely in certain spaces. Of course, as sintered stone manufacturer and supplier, the beginning is the most important from us. We supply you the best quality sintered stone slabs or cut to size countertops directly.

Size: 3200*1600*12mm;2400*1200*6mm; 2700*1200*6mm; 3000*1200*3mm;

Surface: Matt; Polished; Digital glazing; Velvet;

Package: A-frame steel package or sea-worthy wood bundles;

Application: Kitchen appliances and home panel; Interior wall and floor; Bathroom space; Custom furnishing; Door panels; Stairs; Furnitures; Exterior wall;

Features:

1. Great amount of in-stock slabs with various colors and sizes for fast shipment;

2. Advanced manufacturing equipment and half-automated production line;

3. Mature management teams and clean working space;

4. Easy to match quartz slabs in full container;

5. Custom slab size and thickness;

6. Small MOQ for each color;

7. Competitive prices;

8. Free samples;

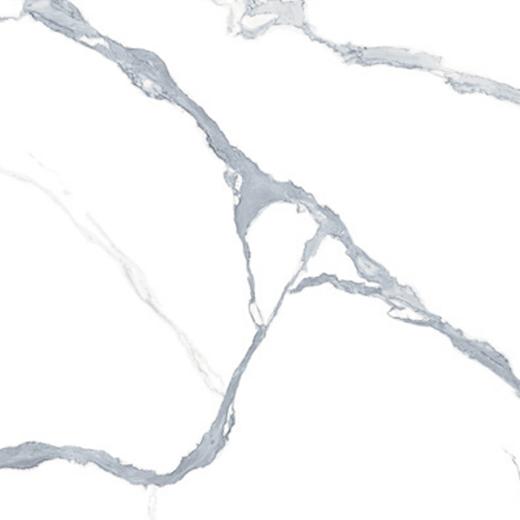

Photos: