Porcelain slab, also called sintered stone slab, is gaining much popularities in modern space decoration. From appearance, it looks very similar to ceramic tiles which have been manufactured and used for decades. The both copy the designs or veins from stone patterns or other construction materials like concrete, wood, etc. However, they still have much difference. Firstly, the biggest size of porcelain slab now is 3200*1600mm with thickness of 6mm, 9mm, and 12mm, which is more possibly to copy full veins of other stone slabs. Moreover, the bigger size avoids too many joints and obviously improve the installation efficiency. In regarding to its performance, since the production of porcelain slabs requires higher standards of machine and equipment, the porcelain slabs are manufactured in higher temperature and compress. Therefore, it shows better features in heat resistance, scratch resistance, zero water absorption, which makes porcelain slab hot in fabrication of kitchen countertops and wall cladding slabs in bathroom or other wall areas. Besides, the porcelain slabs are not much more expensive than ceramic tiles, which is more welcome for average families.

Size: 3200*1600*12mm;2400*1200*6mm; 2700*1200*6mm; 3000*1200*3mm;

Surface: Matt; Polished; Digital glazing; Velvet;

Package: A-frame steel package or sea-worthy wood bundles;

Application: Kitchen appliances and home panel; Interior wall and floor; Bathroom space; Custom furnishing; Door panels; Stairs; Furnitures; Exterior wall;

Features:

1. Great amount of in-stock slabs with various colors and sizes for fast shipment;

2. Advanced manufacturing equipment and half-automated production line;

3. Mature management teams and clean working space;

4. Easy to match quartz slabs in full container;

5. Custom slab size and thickness;

6. Small MOQ for each color;

7. Competitive prices;

8. Free samples;

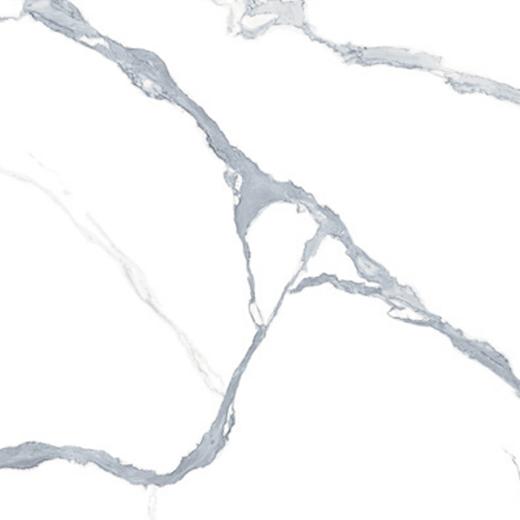

Photos: