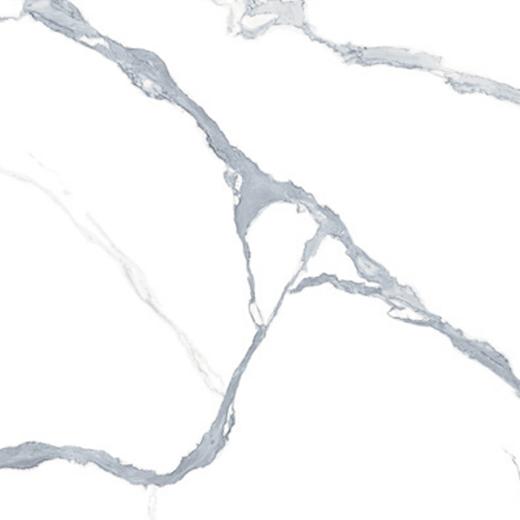

In recent months, the sintered stone is getting hot in many south American countries. Compared to natural marble and marble-veined quartz slabs in performance and prices, the sintered stone seems to be the best choice. It is more welcome for both high-end situations and average families. Firstly, the sintered stone slabs are manufactured under high compress and heat, which produces the slabs with perfect resistance to water, heat, and scratch. Then they are popularly used for wall panels, kitchen benchtops. Besides, the sintered stone slabs, like other artificial stone materials, have flexible capacity to imitate various types of construction material surfaces, like wood, marble, concrete and even silk. The abundance of color patterns satisfies nearly all clients or consumers for their ideal spaces. They could be either traditional and classical styles or modern and technical surfaces. Last but not least, thanks to modern mature manufacturing techniques and advanced production lines, the finished sintered stone slabs are well controlled to a very competitive prices for all clients, which helps them, to a large extent, win much popularities among various types of construction materials, especially among artificial stone types.

Size: 3200*1600*12mm;2400*1200*6mm; 2700*1200*6mm; 3000*1200*3mm;

Surface: Matt; Polished; Digital glazing; Velvet;

Package: A-frame steel package or sea-worthy wood bundles;

Application: Kitchen appliances and home panel; Interior wall and floor; Bathroom space; Custom furnishing; Door panels; Stairs; Furnitures; Exterior wall;

Features:

1. Great amount of in-stock slabs with various colors and sizes for fast shipment;

2. Advanced manufacturing equipment and half-automated production line;

3. Mature management teams and clean working space;

4. Easy to match quartz slabs in full container;

5. Custom slab size and thickness;

6. Small MOQ for each color;

7. Competitive prices;

8. Free samples;

Photos:

Other designs: