Currently popular sintered stone slab is also called porcelain slab. Together with quartz engineered slab, it is also universally used for interior spaces, like kitchen countertop and wall or floor tiles. However, comparatively, the sintered stone is thinner, which eases the fabrication and installation for those fabricators. Besides, for similar design patterns, sintered stone slabs are cheaper than quartz slabs, which receives more popularity among fair families. Moreover, to be honest, glossy surface of sintered stone is more slippery than quartz surface and it is better to be used in bathroom wall. The glossy sintered surface has better function in anti-water, anti-bacteria and anti-stain in such a wet spaces like bathroom or kitchen wall. Of course, thanks to thinner slabs, one container can load much more sintered stone slabs, which helps cut down shipping cost for each slab and become more competitive in prices than quartz stone. Anyway, both quartz slabs and sintered stone slabs are the most popular modern stone materials for interior spaces building.

Size: 3200*1600*12mm;2400*1200*6mm; 2700*1200*6mm; 3000*1200*3mm;

Surface: Matt; Polished; Digital glazing; Velvet;

Package: A-frame steel package or sea-worthy wood bundles;

Application: Kitchen appliances and home panel; Interior wall and floor; Bathroom space; Custom furnishing; Door panels; Stairs; Furnitures; Exterior wall;

Features:

1. Great amount of in-stock slabs with various colors and sizes for fast shipment;

2. Advanced manufacturing equipment and half-automated production line;

3. Mature management teams and clean working space;

4. Easy to match quartz slabs in full container;

5. Custom slab size and thickness;

6. Small MOQ for each color;

7. Competitive prices;

8. Free samples;

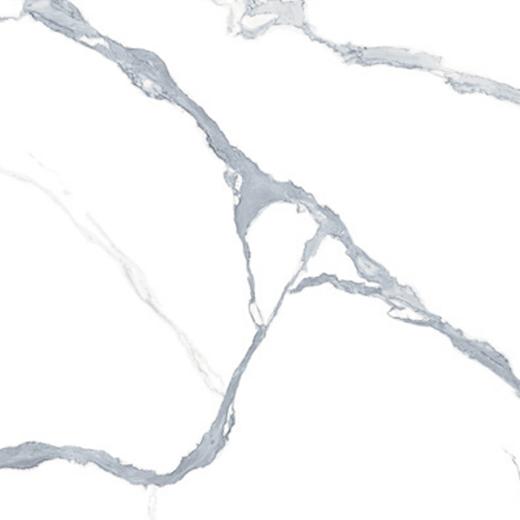

Photos: