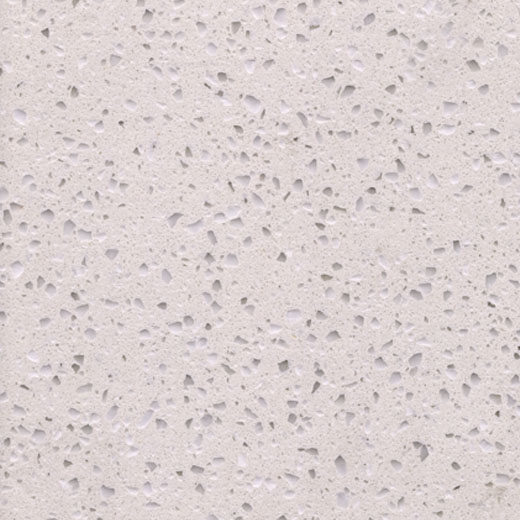

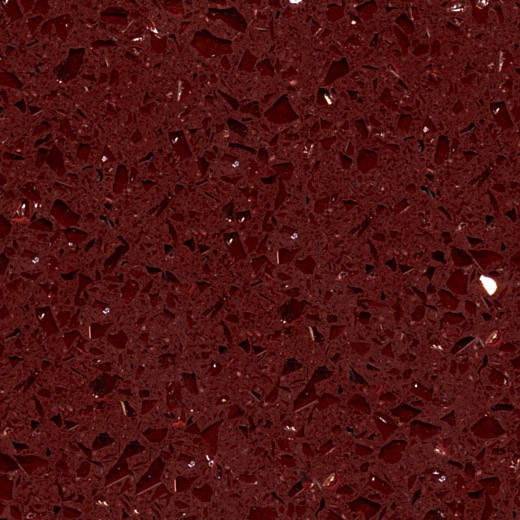

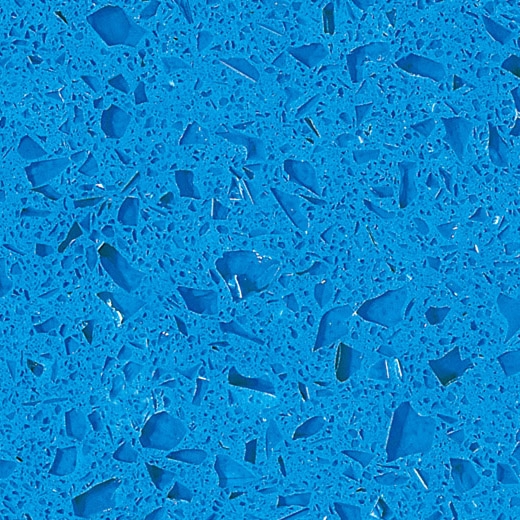

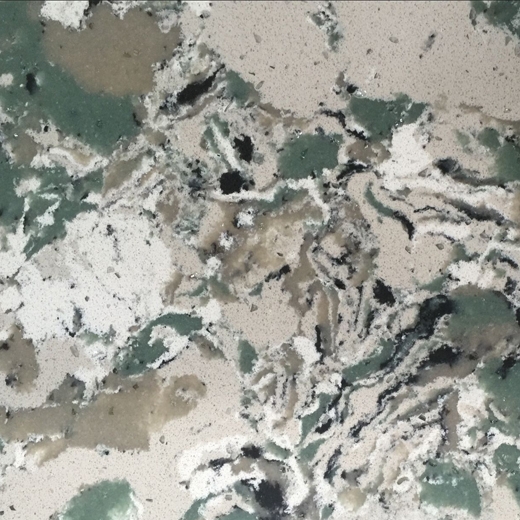

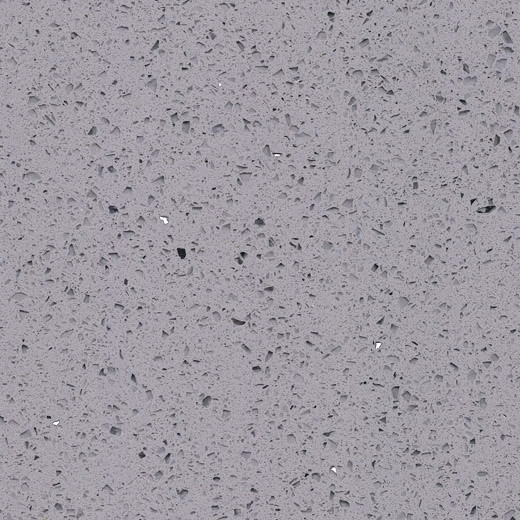

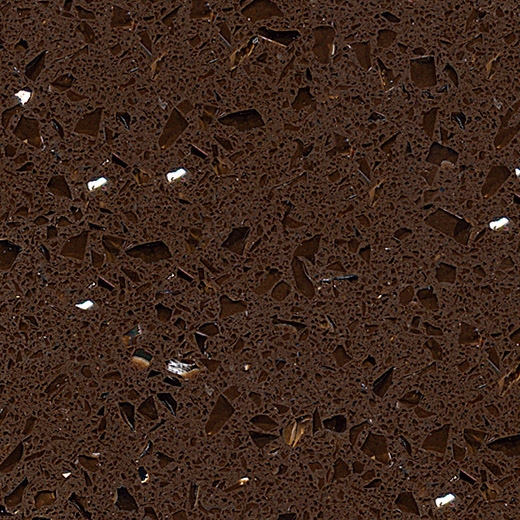

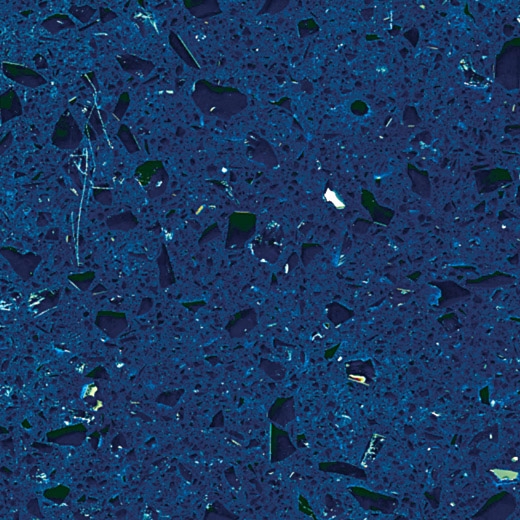

According to governments from Australia and New Zealand, the silicosis is attributed to the natural quartz sand in the manufacturing of engineered quartz slabs. Therefore, the engineered quartz slabs were not allowed to fabricate in these two countries few months ago. For those quartz countertops fabricators, they change back to natural granite or marble and other natural stone. One solution from us is that we manufacture non-silica quartz slab which is to replace natural quartz sand with glass sand. The new glass slabs with glass sand material are well acceptable by these two markets. So our quartz slabs buyers from these two markets have increased much amount of the glass slabs to fabricate their kitchen countertops. You may have questions about difference between old quartz slabs and new glass slabs. Actually, from surface, you can't differentiate them obviously. With same manufacturing equipment and techniques, they are nearly same. Moreover, from physical and chemical performance, both also are very similar to fabricate and use in the same way. However, why new glass slab is more expensive than normal quartz slab? Just because raw material of glass slab is more expensive than quartz sand. We add normally $5-8 dollars per square meter for glass slab, depending on which design our clients need. Anyway, if you are from Australia and New Zealand, we know what glass slab patterns you need and what we can do for you.

| Color | Specifications Choices | Thickness | Loading amount | Gross weight | Package ways |

| Calacatta white | 3200*1600mm/ 126''x63'' | 12mm | 175 slabs | 26880 KG | Sea-worthy wood bundle |

|

|

3000*1400mm/ 120'' x 56'' | 15mm | 140 slabs |

26880 KG |

A-frame rack |

|

|

3000*1600mm | 18mm | 116 slabs |

26880 KG |

Wood box for cut to size top |

|

|

3000*1200mm | 20mm | 105 slabs |

26880 KG |

|

|

|

Customized | 30mm | 70 slabs |

26880 KG |

|

Features:

1. Over 10 production lines in 3 cities to ensure short lead time;

2. Over 200 quartz colors to satisfy needs from different buyers;

3. Self-owned shipping company to get fast shipment if necessary;

4. Free samples available for your promotion in your local market;

5. Customized quartz colors available based on your samples;

6. Different package ways for different markets;

7. Cut to size quartz countertop available with our own workshop;

Detailed photos: